In today's fast-paced expansion of digital infrastructure, the efficiency and quality of fiber optic network deployment are critical. Every splice point is a potential bottleneck for data and a key node for long-term reliability. The evolution from traditional splicing methods requiring high skill to advanced fusion splicing technology represents one of the most significant leaps forward, fundamentally transforming how networks are built. Modern fiber fusion splicers are not just tools for connecting glass; they are sophisticated automated systems designed to deliver unprecedented speed and precision, directly impacting project timelines, installation costs, and network performance.

The right fusion splicer acts as a powerful force multiplier for deployment teams. By automating complex alignment tasks, ensuring consistent weld quality, and integrating diagnostic functions, these devices turn delicate craftsmanship into a reliable, repeatable process. This article explores how contemporary splicers, exemplified by models like the COMPTYCO 6-Motor S-90 Optical Fiber Fusion Splicer, are engineered to accelerate deployment cycles while guaranteeing the precision essential for high-speed, low-latency networks.

The Engine of Efficiency: Core Technologies for Speed

Advanced Motorized Alignment and Automation

At the heart of a modern splicer's speed is its automated alignment system. Six-motor systems, like the one in the S-90, utilize high-resolution cameras and sophisticated software to automatically align fiber cores with sub-micron accuracy in multiple axes. This happens in seconds, completing a full splice cycle (including cleaning, cleaving, alignment, welding, and heat-shrinking the sleeve) in as little as 30 seconds or less for some high-performance models. This automation dramatically reduces the active time and skill required per splice compared to manual methods.

This automation extends to the entire workflow: automatic fiber clamping, automatic gap setting, automatic arc calibration, and automatic splice sleeve heating. The technician's role is streamlined to fiber preparation and loading, allowing a single technician to perform 100-200 high-quality splices in a full day. For large-scale projects, this cumulative time saving translates directly into shorter deployment schedules and reduced labor costs.

Intelligent Processing and User-Centric Design

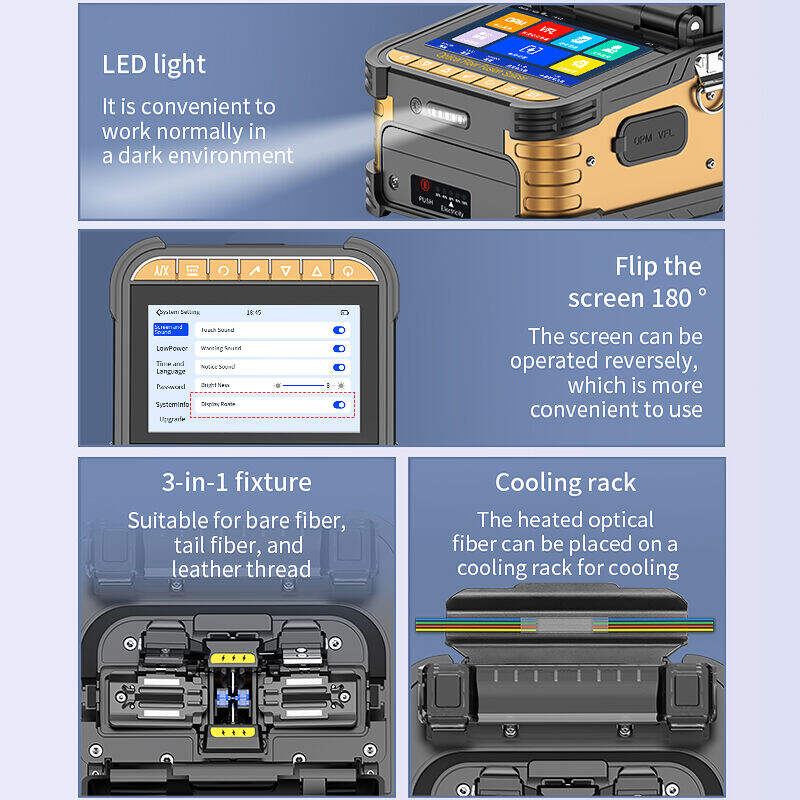

Speed is also achieved through intelligent software and interfaces. A large, responsive touchscreen provides clear, intuitive control and visual feedback. Pre-programmed recipes for various fiber types (SMF, MMF, DSF, etc.) allow technicians to select the correct profile instantly, ensuring optimal parameters for every splice without manual adjustment. Features like one-key operation and batch splicing modes further simplify the process for high-volume work.

Robust power systems are critical for field speed. A high-capacity battery, such as the 7800mAh unit in the S-90, supports a full day's work or hundreds of splices on a single charge, eliminating downtime for power swaps or searching for outlets. This portability and endurance are indispensable for aerial, underground, or remote site work, keeping the deployment team productive anywhere.

The Foundation of Quality: Precision Engineering for Accuracy

Core Alignment and Loss Estimation Technology

While speed gets the job done, accuracy ensures it lasts. The primary determinant of splice quality is the precision of core alignment. Splicers utilizing core alignment technology directly image the fiber's core and cladding. The six-motor system in advanced models provides superior core alignment by making fine adjustments to center the light-guiding core precisely, not just the outer cladding. This results in consistently low splice loss, typically below 0.02 dB for single-mode fiber, which is crucial for meeting the loss budgets of long-haul and high-bandwidth networks.

Integrated optical power meter functionality, often bundled, takes accuracy a step further. After splicing, the technician can immediately test the insertion loss of the link without switching tools, receiving instant, objective verification of splice quality. This closed-loop process prevents poor splices from being installed, reducing future fault locations and network downtime.

Environmental Compensation and Consistent Arc Welding

Field conditions are unpredictable. A top-tier splicer maintains accuracy across temperature, humidity, and altitude changes through automatic environmental compensation. Sensors detect ambient conditions, and the machine self-adjusts critical parameters like arc power and duration to produce a perfect weld every time. This ensures that a splice made in a cold morning manhole is as reliable as one made in a hot afternoon aerial bucket.

The welding process itself is governed by stable, programmable arc discharge. Consistent heat application fuses the glass fibers into a single, homogeneous strand with minimal deformation or stress. Post-splice reinforcement with an integrated heat shrink oven protects the splice point, ensuring long-term mechanical strength and resistance to environmental factors, securing the accuracy of the installation for decades.

Integrated Tools: The All-in-One Advantage for Deployment

Unified Workflow with VFL and Power Meter

Deployment speed suffers when technicians must constantly switch between multiple devices. Modern splicers solve this by integrating essential tools. A built-in visual fault locator uses a bright red laser to visually trace fiber, identify breaks, verify continuity, and find macro-bends – invaluable for troubleshooting during installation and testing. As mentioned, an integrated optical power meter allows for immediate loss validation.

This consolidation means a technician carries, manages, and charges only one primary device instead of three or four. It reduces setup time at each splice location, minimizes the risk of leaving a necessary tool behind, and simplifies training. The COMPTYCO S-90 exemplifies this "complete equipment" approach, bundling core functions to create a seamless, efficient field workflow.

Data Management and Multi-Language Support

Accuracy extends to record-keeping. Advanced splicers can store thousands of splice records with images and loss data, which can be exported for quality assurance reports and asset management. This digital trail is essential for maintaining accurate network documentation.

For global deployment teams or diverse workforces, multi-language support (like the ten languages offered on the S-90) removes a significant barrier. Technicians can operate the machine in their native language, reducing configuration errors, improving comprehension of prompts, and accelerating overall proficiency, thereby enhancing both the speed and accuracy of the entire team's output.

Impact on Project Economics and Network Performance

Direct Benefits to Deployment Cost and Timeline

The combined speed and accuracy translate into direct bottom-line benefits. Reduced labor costs come from faster splice cycles and fewer reworks, meaning projects require fewer man-hours. Accelerated deployment allows network operators to bring services online and start generating revenue sooner. High first-splice success rates minimize wasted fiber, splice protectors, and other consumables. Fewer tools to purchase and lower long-term training costs improve return on investment on equipment.

Ensuring Long-Term Network Reliability

The accuracy delivered by modern splicers is an investment in network integrity. Low-loss, low-reflection splices ensure signals travel farther and cleaner, maximizing the bandwidth and reach of the installed fiber. High-quality splices fail less often. This dramatically reduces the costly truck rolls and troubleshooting associated with network outages, lowering the total cost of ownership over the network's lifespan. Networks built with precise fusion splicing are better prepared to support next-generation technologies like 5G, XGS-PON, and dense wavelength-division multiplexing, which have stringent loss budgets.

FAQ: Fusion Splicer Performance

How much faster is a modern fusion splicer compared to older methods?

A modern automated splicer can complete a high-quality splice cycle, often in under 30 seconds. This is significantly faster and more consistent than older, manual alignment methods. A trained technician can perform between 100 to 200 splices in a full day of field work with such equipment.

What does "6-motor alignment" mean, and why is it important?

It refers to a system using six independent, precision motors to control the position of each fiber end. This allows for true core-to-core alignment on multiple axes, superior to systems that only align the fiber's outer cladding. The result is lower and more consistent splice loss, especially critical for single-mode fibers used in telecommunications.

Can the integrated optical power meter replace a standalone unit?

For most field installation tasks and basic acceptance testing, yes. An integrated optical power meter is perfectly suited for measuring splice loss and verifying link power levels on the spot. It covers the vast majority of field needs, streamlining the workflow.

How does a fusion splicer maintain quality in different environments?

Professional-grade splicers are equipped with environmental sensors. The system automatically compensates by adjusting the arc welding parameters for factors like temperature, humidity, and air pressure (altitude). This ensures consistent, high-quality splice results whether working in a desert, a humid climate, or at high elevation.