High-precision cable work demands tools that combine accuracy, durability, and efficiency. As fiber optic networks expand into increasingly complex environments, the importance of proper cable preparation cannot be overstated. The right fiber stripper not only protects delicate glass fibers from damage but also ensures consistent, reliable terminations that maintain optimal signal integrity.

Professional technicians working in telecommunications, data centers, and specialized installations understand that choosing the appropriate stripping tool directly impacts installation quality and long-term network performance. With multiple cable types, coating materials, and environmental challenges, selecting the ideal stripper requires careful consideration of both technical specifications and practical application requirements.

Understanding High-Precision Stripping Requirements

The Critical Role of Precision in Fiber Optic Work

Optical fibers, particularly single-mode variants with core diameters as small as 9 microns, demand extraordinary precision during preparation. Even microscopic imperfections or scratches on the glass surface can scatter light, creating insertion loss and back reflection that degrade network performance. High-quality stripping eliminates these risks by removing protective coatings cleanly without contacting or damaging the underlying glass.

Different fiber types present unique challenges: tight-buffer cables require different techniques than loose-tube designs, while specialty fibers like bend-insensitive variants may have unique coating compositions. The stripping tool must accommodate these variations while maintaining consistent performance across hundreds or thousands of terminations in field conditions.

Multi-Tool Advantages for Field Technicians

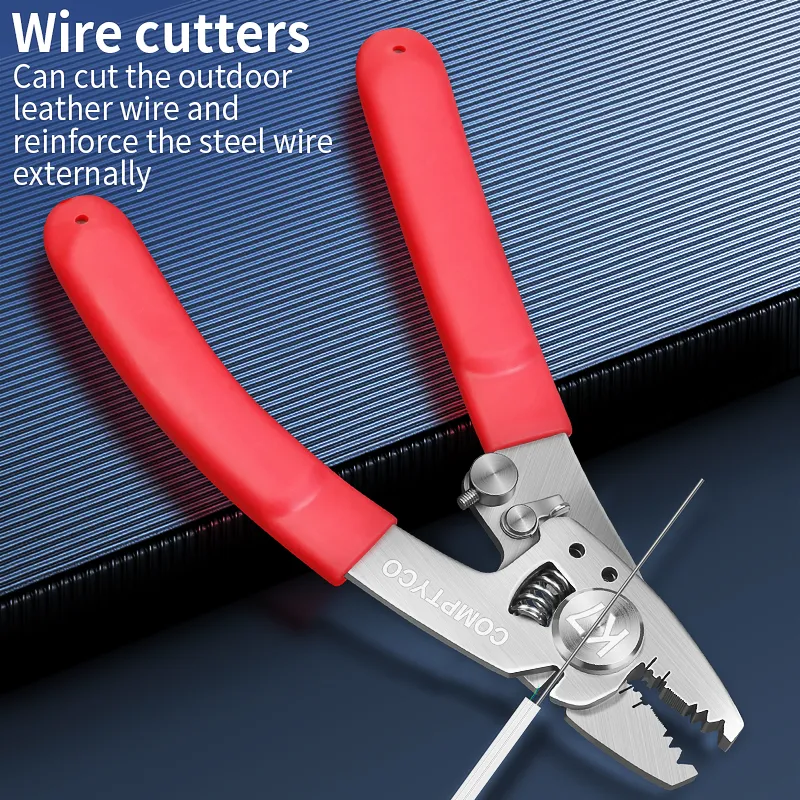

Versatile tools like the K7 Seven-in-One Wire Stripping Tool offer significant advantages for technicians working across diverse installations. By integrating multiple stripping ports into a single device, these tools eliminate the need to carry numerous specialized strippers while ensuring the correct blade configuration is always available. This consolidation reduces setup time and minimizes the risk of using incorrect tools for specific cable types.

The efficiency gains extend beyond mere convenience. When technicians can quickly select the appropriate stripping diameter from an integrated tool, they maintain workflow continuity and reduce cable preparation errors. This becomes particularly valuable in confined spaces like aerial buckets, underground vaults, or crowded data center racks where tool accessibility is limited.

Key Selection Criteria for Precision Fiber Strippers

Blade Material and Construction Quality

High-precision stripping begins with exceptional blade quality. Stainless steel blades, particularly those with precision-ground edges and specialized coatings, provide the durability needed for consistent performance across numerous cable preparations. The blade geometry must be optimized to cut through various coating materials—acrylate, carbon, nylon, or polyethylene—without applying excessive force that could deform or fracture the glass fiber.

Blade retention mechanisms deserve equal consideration. Secure, adjustable blade holders maintain alignment through extended use, preventing the blade wobble that creates uneven cuts. Quick-change blade systems offer additional efficiency benefits for high-volume operations, though fixed-blade designs often provide superior stability for the most demanding precision applications.

Ergonomic Design and Operational Features

Field technicians may perform hundreds of stripping operations daily, making ergonomic design essential for productivity and safety. Comfortable, non-slip handles reduce hand fatigue while providing positive control during the stripping motion. Weight distribution affects handling precision, with balanced tools offering better control than front-heavy alternatives.

Adjustable stripping length stops ensure consistent coating removal, eliminating guesswork and reducing rework. Clear visual indicators for different cable diameters help technicians quickly select the correct setting, particularly valuable in low-light conditions common to many installation environments. Spring-assisted opening mechanisms further reduce hand strain during repetitive operations.

Specialized Applications and Tool Configuration

FTTH and Access Network Requirements

Fiber-to-the-home installations present unique challenges with diverse cable types encountered in single deployments. Drop cables, indoor/outdoor cables, and distribution fibers each have different coating structures requiring specific stripping approaches. Multi-port strippers configured for common FTTH cable diameters (900μm, 2.0mm, 3.0mm) enable technicians to handle these variations efficiently without changing tools.

The compact nature of many access network installations demands tools with minimal clearance requirements. Strippers with slim profiles and rotating blade heads facilitate work in tight spaces behind wall plates, within termination boxes, or at crowded pedestals. Corrosion-resistant materials become particularly important for outdoor applications where tools face weather exposure.

Data Center and High-Density Environments

Data center technicians prioritize speed and precision when preparing high-count fiber cables for termination. Tools must accommodate tight-buffered fibers common in premises applications while providing clean stripping on individual fibers within ribbon cables. Precision stops and guides ensure consistent stripping lengths critical for proper placement in high-density connectors and splices.

Static control features gain importance in data center environments where electrostatic discharge could damage sensitive electronics. Non-conductive handles and static-dissipative materials protect both the fiber and surrounding equipment during preparation. Magnetic part catchers or integrated debris management systems help maintain cleanliness in critical installation areas.

Technical Specifications and Performance Metrics

Precision Tolerances and Repeatability

Professional-grade stripping tools should specify clear performance tolerances for both stripping diameter and length consistency. High-precision tools typically maintain diameter accuracy within ±0.05mm, ensuring clean coating removal without glass contact. Length repeatability within 0.5mm prevents variations that could affect subsequent termination or splicing processes.

Blade edge retention specifications indicate how many clean strips can be performed before blade replacement. Quality hardened steel blades typically maintain optimal performance through 5,000-10,000 stripping operations depending on coating materials. Some premium tools include wear indicators that alert technicians to blade degradation before quality is compromised.

Material Compatibility and Testing

Documented compatibility with various cable types provides confidence in tool selection. Look for tools tested with specific cable manufacturers' products or industry-standard coating types. Temperature operating ranges ensure reliable performance across different environments, particularly important for technicians working in varying climatic conditions.

Independent testing results or industry certifications (where applicable) offer objective performance validation. Some manufacturers provide sample cables for testing tool compatibility with specific installations, a valuable option when working with proprietary or unusual cable designs.

Cost Considerations and Value Assessment

Total Cost of Ownership Analysis

While initial purchase price matters, the total cost of ownership provides a more accurate assessment of tool value. Consider blade replacement costs, maintenance requirements, and expected service life when comparing options. Tools with higher initial costs but superior durability and lower maintenance often prove more economical for professional use.

Productivity impacts represent another crucial economic factor. Tools that reduce preparation time, minimize rework, and decrease training requirements deliver ongoing value beyond their purchase price. For contractor operations, these efficiency gains directly translate to increased job capacity and profitability.

Warranty and Support Services

Comprehensive warranties protect against manufacturing defects and unexpected failures. Look for warranties covering both materials and workmanship, with clear terms regarding normal professional use. Manufacturer support availability—including technical assistance, repair services, and replacement part access—ensures continued productivity if issues arise.

Training resources, whether included with purchase or available separately, help technicians maximize tool performance. Instructional videos, detailed manuals, and application guides reduce learning curves and promote proper technique from initial use.

Best Practices for Tool Maintenance and Operation

Routine Maintenance Procedures

Regular cleaning removes coating residue that accumulates on blades and working surfaces, maintaining cutting precision. Manufacturer-recommended lubricants applied to moving parts prevent binding and ensure smooth operation. Storage in protective cases prevents blade damage and maintains calibration during transport between job sites.

Periodic inspection for blade wear, spring tension, and alignment ensures continued precision. Establishing regular maintenance schedules based on usage volume prevents unexpected degradation during critical operations. Proper blade replacement following manufacturer guidelines maintains original performance specifications.

Technique Optimization for Different Cables

Adapting stripping technique to specific cable types maximizes both tool performance and preparation quality. Tight-buffered cables typically require different handling than loose-tube designs, while ribbon fibers demand specialized approaches. Practicing on scrap cable before working on live fibers develops proficiency without risk to operational networks.

Understanding cable construction helps technicians select optimal stripping parameters. The number of coating layers, material properties, and temperature conditions all influence stripping approach. Documenting successful techniques for specific cable types creates valuable reference material for future installations.

FAQ

What makes a fiber stripper suitable for high-precision work?

High-precision fiber strippers feature precision-ground blades with exacting tolerances, ergonomic designs for controlled operation, adjustable stops for consistent stripping lengths, and compatibility with specific cable diameters. Materials like hardened stainless steel ensure durability while maintaining sharp edges through extended use.

How many different cable sizes should a field technician's stripper accommodate?

Most field applications require handling ranging from 250μm bare fiber to 3.0mm tight-buffered cables. Multi-port tools like the seven-in-one strippers efficiently cover this range while minimizing tool changes. Specialized applications may require additional sizes, but these cover most routine installations.

What maintenance do precision fiber strippers require?

Regular cleaning after use, periodic lubrication of moving parts, blade inspection for wear, and proper storage in protective cases maintain optimal performance. Blades should be replaced according to manufacturer recommendations or when cutting quality diminishes. Annual calibration checks ensure continued precision.

Can one stripper handle all types of fiber optic cables?

While multi-port strippers handle most common cables, specialized designs like ribbon fiber, military tactical cables, or unusual diameters may require dedicated tools. For general telecommunications, data center, and FTTH work, a well-configured multi-port stripper typically suffices for 90-95% of applications.